Now is the Time for Sodium-Ion Batteries in Electric Vehicles!

Recent progress with Sodium-Ion batteries makes them suitable for electric vehicles, with decisive advantages over existing technology. Production of EVs with these new batteries has started in China.

(l’article est aussi disponible en français.)

Imagine you decide to purchase an electric car. There are two models - let’s call them Model L and Model S - in front of you.

The two EVs are extremely similar, yet there are important differences.

Model S is 15% cheaper, has 15% less range, recharges twice faster, and does not loose 20 to 40% range in the winter.

Model S is actually only different from Model L in that it has a different battery pack.

Model S has a Sodium-Ion battery while Model L has a Lithium-Ion battery pack.

Model S is much cheaper because its battery largely relies on very cheap and abundant sodium.

Model L uses all sorts of minerals — not only lithium but also cobalt, graphite and others - that are more expensive, require massive mining, sometimes in very poor ecological or social conditions, and are usually imported.

Oh, I forgot: even if the fire risk with model L is very very small — we are told — it’s essentially nil with model S.

Facing this choice between Model S and Model L, what will you choose?

Chances are high that you will choose model S, i.e. that you will choose the Sodium-Ion battery.

Why is Sodium-Ion Technology Emerging as a Solution for EVs?

Sodium-Ion battery technology has been in existence for some years, as developed in the 70s and early 80s. The technology relies on sodium ions as its charge carriers, and is lithium-free.

Yes, Sodium, the same sodium element (precision: not the same salt) that you can find in the (sea) salt in your kitchen.

Working principles and cell construction are usually similar to those of lithium-ion batteries, yet lithium is replaced with sodium as the cathode material.

Until recently, the emphasis in EV battery development has been to rely on Lithium, as offering more potential for energy density, power and range.

The increasing demand and price for Lithium, and the growing difficulty to source it, have brought battery manufacturers and researchers to have a second look at Sodium-based batteries.

Today, the performance of Sodium-based batteries is very close to that of the LFP (Lithium - Iron - Phosphate) batteries, used by Tesla and other manufacturers for several models.

LFP batteries, even if not the most energy dense, are increasingly embraced by battery manufacturers and automakers because they cost less to produce.

It’s not known what is the current exact gap between LFP batteries and Sodium-Ion batteries. This is because research and development is extremely active and largely kept secret for intellectual property reasons.

What is abundantly clear from various recent articles is that the performances of Sodium-Ion batteries are very close to those of LFP batteries. There is also substantial headroom for improvement.

The largest battery manufacturer CATL, from China, has already embraced the Sodium-Ion technology.

“CATL’s first-generation sodium battery generates 160-watt-hours per kilogram. This is 10% less energy than iron LFP batteries. … CATL plans to increase the energy density of next generation sodium ion to 200 Wh/kg,” reads this September 2023 article.

The energy density of batteries is a key metric. It’s the amount of energy, in Wh, that can be stored in 1 kg of battery.

Best available Lithium-based batteries have energy densities in the high 200s (example: an estimated 272 to 296 Wh/kg for Tesla’s 4680 model).

Numbers vary regarding the equally evolving LFP technology, but it’s usually estimated to offer at least 160 Wh per kg density at the battery level. See techbuzzer and greencarcongress references.

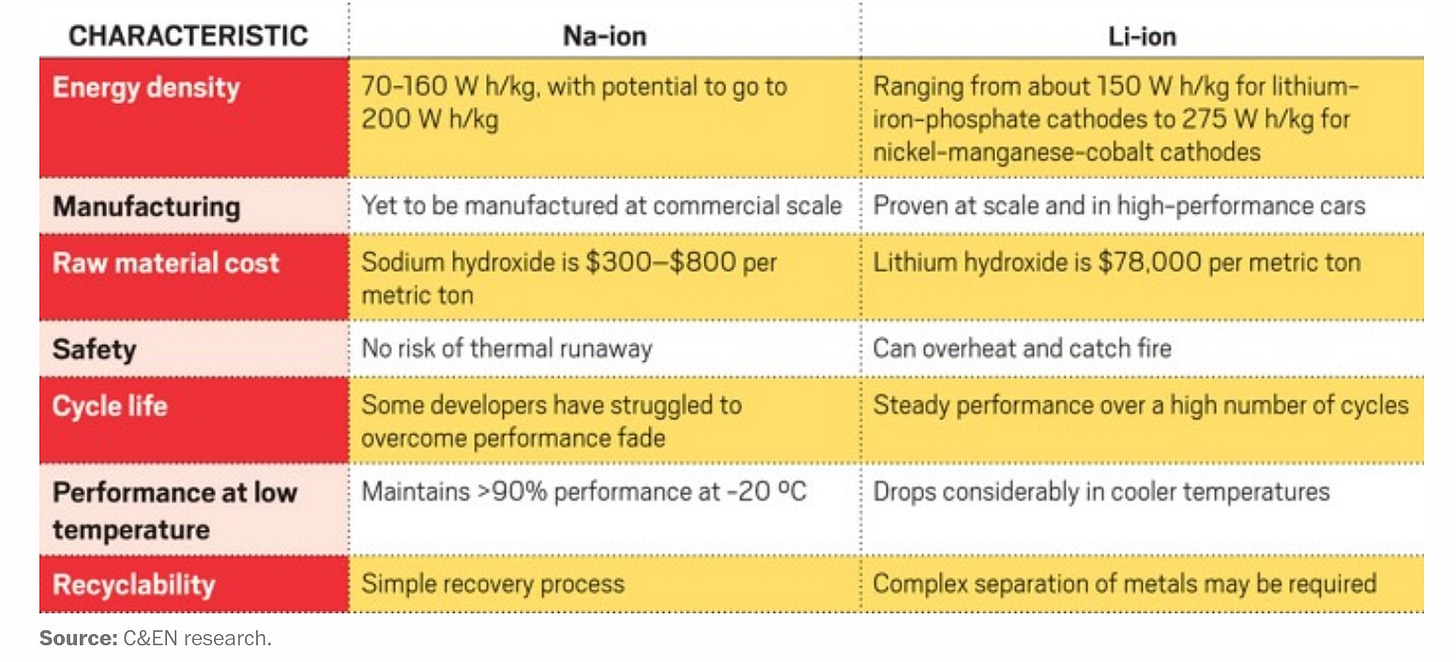

An excellent article about Sodium-Ion batteries was published in May 2022 in Chemical & Engineering News. You are invited to read it. Here is the comparison between Na-Ion and Li-Ion they produced.

Some EVs are Being Equipped with Sodium-Ion Batteries

The main manufacturer that has started, or is due to imminently start, the production of EVs equipped with Sodium-Ion batteries, is China-based BYD.

BYD has announced it would start producing its Seagull Model with a Sodium-Ion battery, and will do so next with its just a bit larger Dolphin model.

All of these are ongoing developments, and we should get details about the pricing and the real world performances of these vehicles in the next weeks or months.

Note that the Seagull’s announced base price, in China, equipped with a Lithium-Ion battery, is very low, at only US$11,300.

The Sodium-Ion version may be announced at an even lower price.

As we discussed previously, such competitively priced models represent a potential great opportunity for consumers in Western countries, but are seen as a vital threat by automakers in Europe and North America.

Indeed, automotive industries in high labor cost economies will find it extremely difficult to compete in the marketplace with such vehicles.

What EVs are Suitable for Sodium-Ion Batteries?

At this juncture, all the vehicles suitable to be equipped with LFP batteries should, in principle, be suitable, if not today, in a very near future, to be equipped with Sodium-Ion batteries.

Tesla is already using the LFP technology for some versions of its two best selling vehicles: Model 3 and Model Y.

Ford and GM have announced they will move to LFP technology, for vehicles such as the Lightning EV truck and the EV Bolt.

There is no information according to which Sodium-Ion batteries are already in the pipeline for hybrid vehicles, but that would appear to be an excellent move, given the smaller size of those batteries and the fire and other battery issues that also exist with those vehicles.

Sodium-Ion Technology Offers Considerable Advantages

What would be the advantages of a bold move to Sodium-Ion batteries? They are many and this includes:

* the batteries would be expected to cost less than half the price of current batteries, which are by the far the most pricey part of EVs

* the selling prices of the vehicles equipped with Na-Ion batteries would be substantially lower

* the cost of the batteries would not be expected to fluctuate significantly, because there wouldn’t be a high dependence on pricey imported minerals

* reliably sourcing the required minerals would be much less of an issue; there would not be a high dependence on foreign suppliers

* sodium-ion batteries are expected not to lose capacity the way lithium batteries do, so the performance of the battery would last much longer

* the longevity of the vehicles would accordingly be higher and the resale values would not drop because of the uncertainties associated with the battery

* even if a battery replacement is needed at some point, because of a crash, or with age, it will be much less expensive

* presently available information suggests that recycling of Sodium-Ion batteries will be much simpler and less costly than with the presently used battery technologies

* the issue of fire, which is a real issue with EVs, would be considerably reduced, which will eliminate the fire-related fear to purchase and drive an EV

* the associated issues and high costs for fire prevention (more distance between vehiles, installing sprinklers, etc.) in car parks, garages, etc. would mostly vanish

* the considerable reduction in fire risk and the lower replacement cost in case of battery damage, will make EVs again insurable at decent premiums

* the vehicle would be more suitable for colder climates, including the Northern USA and Canada; as current batteries can lose up to 40% range in winters

* the vehicle would also be more suitable to hot climates, as there are also range issues with high temperatures, in the Southern USA for example

In terms of downsides, there may still be some technology challenges to address, but apart from that, it’s hard to find any.

Now is the Time!

Sodium-Ion batteries may be, or actually are, the EV revolution in the making.

All the EV manufacturers should now aggressively work to introduce this technology into their vehicles line-up, similarly to what Tesla recently did with LFP technology.

Talking about Tesla, the company can certainly phase in efficient Sodium-Ion batteries within a reasonable time frame of one or two years, and implement it for all its base-models, including its CyberTruck.

BYD is leading the way with the Seagull and the Dolphin but will likely pursue the Sodium-Ion route with additional models.

Likewise, other producers such as Ford, VW, Stellantis, GMC, should adopt this technology, and further improve it.

While the energy capacity gap with Lithium based batteries has already been reduced, there is still scope for improvement of the technology.

It must be noted that existing battery factories can be retro-fitted to produce Sodium-Ion batteries. No big capital expenditures would be needed.

Sodium-Ion batteries is a major technological change in the world of EVs, and should have huge, positive, impacts for all EV manufacturers.

Of course, adopting these batteries will have considerable implications in terms of the supply chain for the required minerals and for future investments.

For example, the multi-billion $ investments recently decided upon in Canada for battery manufacturing will need to be thoroughly revised or reconsidered, in light of this new technology.

Without any reliance on minerals such as Lithium and Cobalt, which have well documented negative environmental and social impacts, like child labor in Africa in the case of Cobalt and watertable depletion in South America in the case of Lithium, EVs will become much more acceptable to the public.

Of immediate concern to EV users are the fire risks, the slow charging time, the range loss in the cold, among other issues, which are making EVs less and less desirable, as there is growing awareness of these issues in the population.

The Sodium-Ion technology has the considerable advantage of simultaneously addressing several of those issues, while at the same time reducing the vehicles’ prices.

From a public policy perspective, Sodium-Ion batteries can be expected to make EVs much more appealing to growing numbers of drivers. Free and informed choice would rule consumer decisions rather than the mandates, subsidies and other market distortions presently implemented by governments.

It’s worth noting too that, if the faster charging time is confirmed, fewer charging stations will be required, which will generate considerable savings both in terms of installations of new charging stations and their maintenance.

The very reputation of EVs is actually at stake, as there are just too many issues with them and their current batteries. Anyone can easily understand they are not the “clean” or “green” vehicles that governments and other EV promoters pretend.

If adopted, the Sodium-Ion battery technology may well be the decisive factor that will make the EV experiment succeed.

Post Scriptum

This is the post #10 in this EV series! And this conclusion brings me back to post #1, where I explain how, some 50 years ago, I was extensively informed about EVs by my late cousin Pierre, who did his engineering thesis about them.

My cousin, who did his whole career in the field of electric mobility, already explained to me at the time that the batteries were the key issue, the Achilles’ heel, of EVs.

It looks like this issue is now being finally resolved with Sodium-Ion batteries.

And still burning fossil fuels to acquire/transport the materials, operate the plants to build the components/vehicles, ship to destination, charge, and eventually haul the dead batteries off.

Your Model S may be less expensive but not enough to make them affordable/viable for the masses worldwide. It’s a neat experiment that is destined to become extinct. EV’s are bankrupting automakers, it won’t be much longer before Tesla is the last man standing...and for how long?

That's all very well. Or isn't. What's the good of it when there won't be enough electricity to charge the things and the "energy transition" is just another wealth-transfer scam?